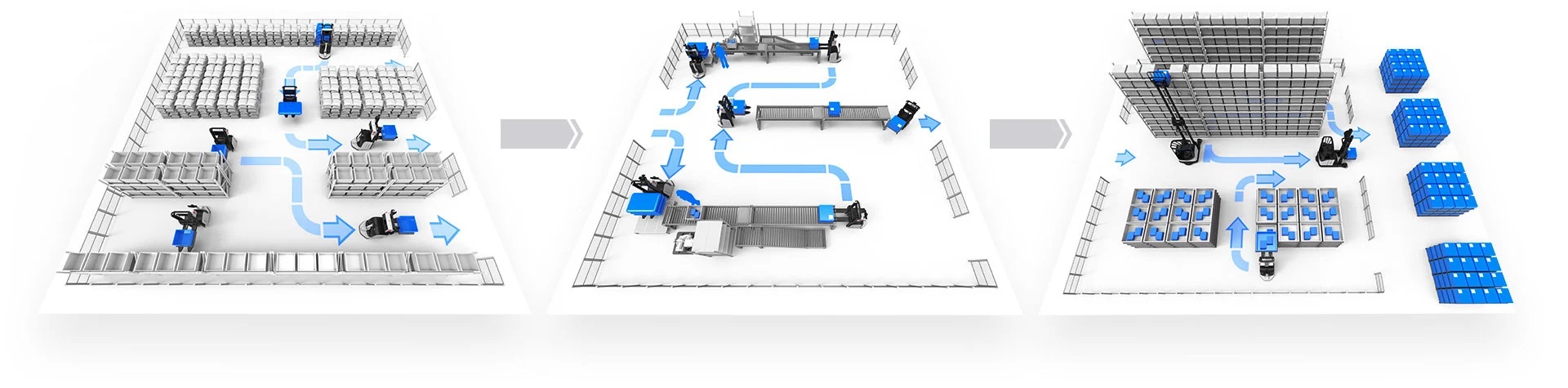

Innovative smart forklift automates full process storage scenario

Pallet Truck

Stack Truck

Reach Truck

VNA Truck

Counterbalance Truck

Body type

Pallet Truck

Stack Truck

Stacker CB

Reach Truck

Vna

Counterbalance Truck

–

Weight (with battery)

867

1215

2211

2940

12793

5650

kg

Payload

2000

1400

1600

1600

1500

3500

kg

Max speed

2

2

2

2

2.2

2

m/s

Navigation

LidarSLAM

LidarSLAM

LidarSLAM

LidarSLAM

LidarSLAM

LidarSLAM

–

Position precision

±10

±10

±10

±10

±10

±10

mm

Communication

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

WIFI,support

2.4G/5G,

IEEE802.11

b/g/n

–

Dimensions

2089 x 877 x 2058

2261 x 897 x 2076

3270*890

2600 x 1450 x 3910

3928*1750

3600 x 1500 x 2725

mm

Lift height

/

2924

3944

9455

12215

4050

mm

Path width

3000

3000

4250

3500

1800

4500

mm

Battery

Lithium-ion, 24V/275Ah

Lithium-ion,24V/225Ah

Storage battery,24V/4Pzs

Lithium-ion,48V/450Ah

Lithium-ion,80V/930Ah

Lithium-ion,48V/450Ah

–

Charge mode

Automatic/

Manual

Automatic/

Manual

Automatic/

Manual

Automatic/

Manual

Automatic/

Manual

Automatic/

Manual

–

Battery life

1500

1500

1500

1500

1500

1500

times

Charging time

<3

<3

<3

<3

<3

<3

h

Run time

6~8

6~8

6~8

6~8

6~8

6~8

h

Obstacle

detection

sensor

Safety Lidar+3D camera

Safety Lidar+3D camera

3D Camera+360°safety (Option)

Safety Lidar+3D camera

3D Camera+360°safety (Option)

Safety Lidar+3D camera

–

Collision

detection

Safety edge

Safety edge

Safety edge

Safety edge

Safety edge

Safety edge

–

Fork detection

Safety edge

Laser

Available

Laser

Available

Laser

–

Goods

identification

3D camera

3D camera

3D camera

3D camera

3D camera

3D camera

–

Goods

detection

Available

Available

Available

Available

Available

Available

–

Acousto-optic

caution

Available

Available

Available

Available

Available

Available

–

Operation

temperature(only

for discharge)

-10~40

-10~40

0~40

-10~40

0~40°

-10~40

°C

Charging

temperature

0~40

0~40

0~40

0~40

0~40°

0~40

°C

Charging

temperature

0~40

0~40

0~40

0~40

0~40°

0~40

°C

Humidity

10~95%,

No condensation

10~95%,

No condensation

10~95%,

No condensation

10~95%,

No condensation

10~95%,

No condensation

10~95%,

No condensation

–

Full process storage scenario

Automate all materials handling process in multiple scenarios, saving labor cost significantly

Multi-advantage forklift solution,

realizing unmanned storing and fetching

- The mirrorless laser SLAM solution provides high accuracy and stability

- The 360° safety solution can reduce the risks of accidents

- It supports the interaction with multiple devices, to facilitate the application in multiple scenarios

- Multi-scenario task templates can be easily configured and directly used

- The intelligent storage location management enables seamless data connection with the WMS

- Multiple business strategies can be flexibly use to meet complex needs

Production line transfer

Automatic supply and removal of raw materials, product line transfer, finished product delivery and docking

Pallet handling

Automatic pallet handling with simple configuration

High level storage

Flexible for storage of goods at different hight

Intensive storage

Automatic storage of goods in warehouse without shelves

Creating unmatchable values for clients

Labor Cost Reduction

- Saves 50%-80% of labor costs

- Reduces intangible personnel management cost

- Reduces man-made security risks

- Operates with lights off, thus reducing energy bills

- ROI in less than 3 years

Operational Safety

- Capable of continuous operation without compromising efficiency

- High operational accuracy with SLAM navigation + visual recognition

- 360-degree obstacle avoidance

- No single point of failure; capable of continuous operation without accident

Flexible Deployment

- Robots come in multiple models, suitable for a variety of logistics scenarios

- Supports multiple system deployment modes

- Supports interaction among multiple devices

Covering full application scenarios

Suitable for bin and pallet handling in multiple industries, with strong and stable performance

Low-level storage

Point-to-point pallet handing

High-level storage

Production line transfer

Shelf storage

Intensive storage

VNA storage