Typical Algorithm Application 01

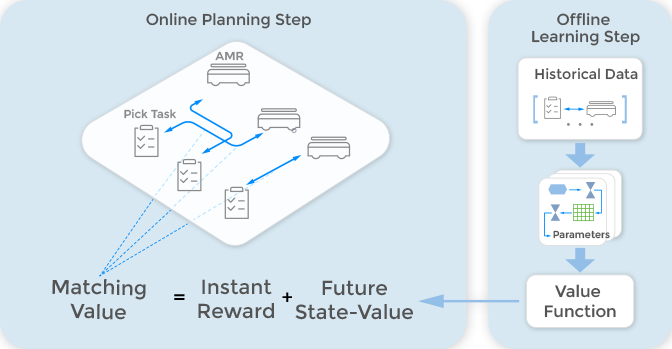

Task Matching

Driven by the historical matching experience data, the shelves to be moved are matched with the mobile robot (AMR) one by one, and the current and future reward values are maximized by the combination of online and offline learning. Then the optimal matching strategy is obtained through continuous iterative learning.

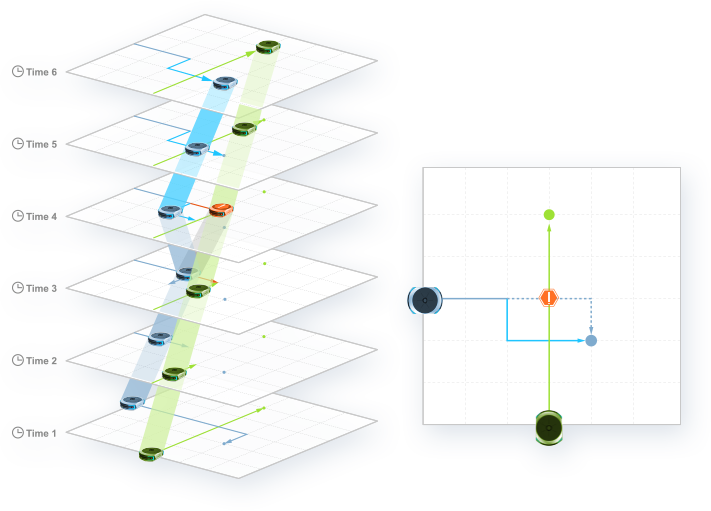

Typical Algorithm Application 02

Path Planning

Breaking the limitation of the traditional way of path planning, the algorithm of deep reinforcement learning and dynamic programming is adopted to proceed multi-agents distributed collaborative path planning, so as to reach the destination in the shortest time while ensuring safe obstacle avoidance.

Typical Algorithm Application 03

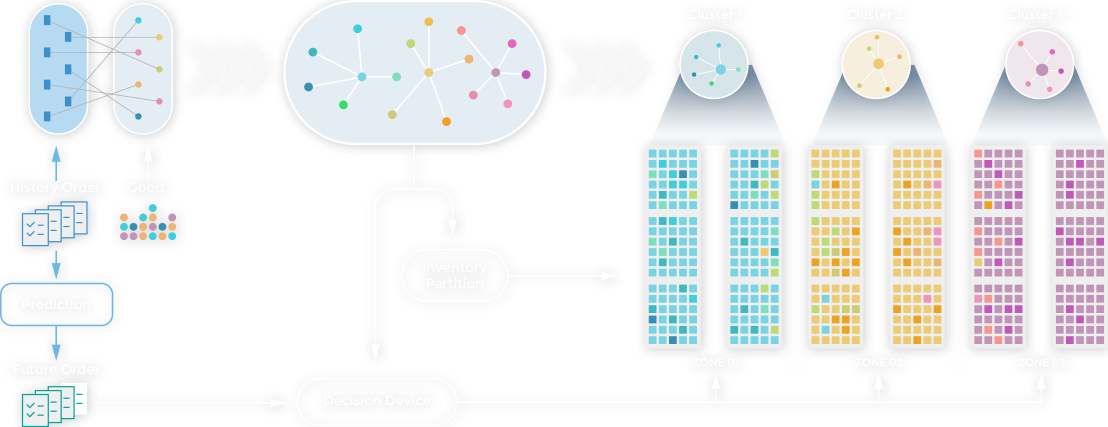

Order Grouping

By mining and analyzing massive historical order data, and predicting future orders, the optimal order wave combination can be obtained through feature extraction, association analysis and unsupervised clustering.

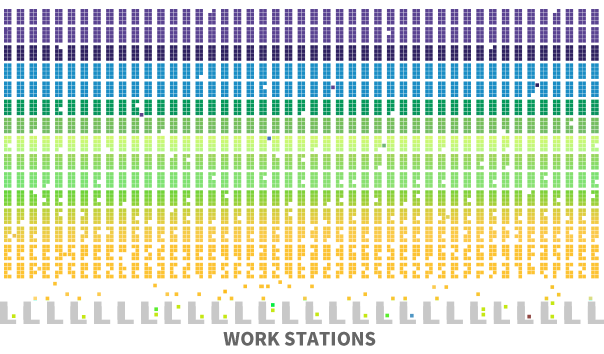

Typical Algorithm Application 04

Shelf Adjustment

Based on the prediction of future order demand, the shelves are likely to be transported is computed, and the robot handling tasks are generated to adjust the shelves to the most suitable position in the warehouse, so as to minimize their overall travel distance.

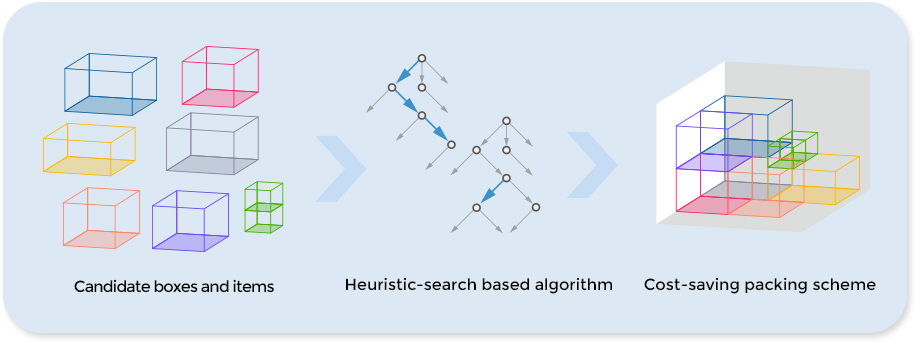

Typical Algorithm Application 05

3D Bin Packing

Our algorithms recommend different box sizes according to the volume information of the ordered goods, which minimizes the cost of packaging materials and improves the packaging efficiency through repeated heuristic search.

Typical Algorithm Application 06

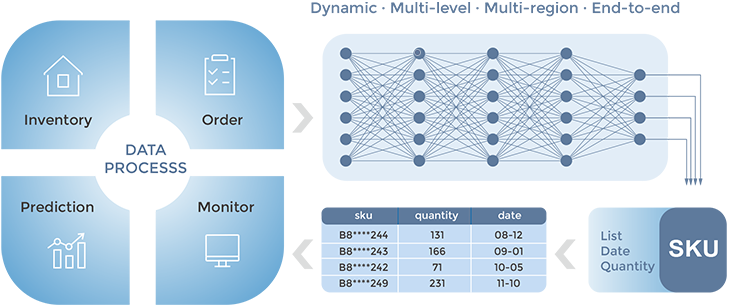

Smart Replenishment

A data-driven end-to-end inventory replenishment model is adopted. Based on real-time monitoring of warehouse status and order sales within the cycle time, a deep neural network is employed to not only generate multi-level and multi-area replenishment plans, but also avoid the impact of the bullwhip effect and greatly improve the replenishment accuracy.