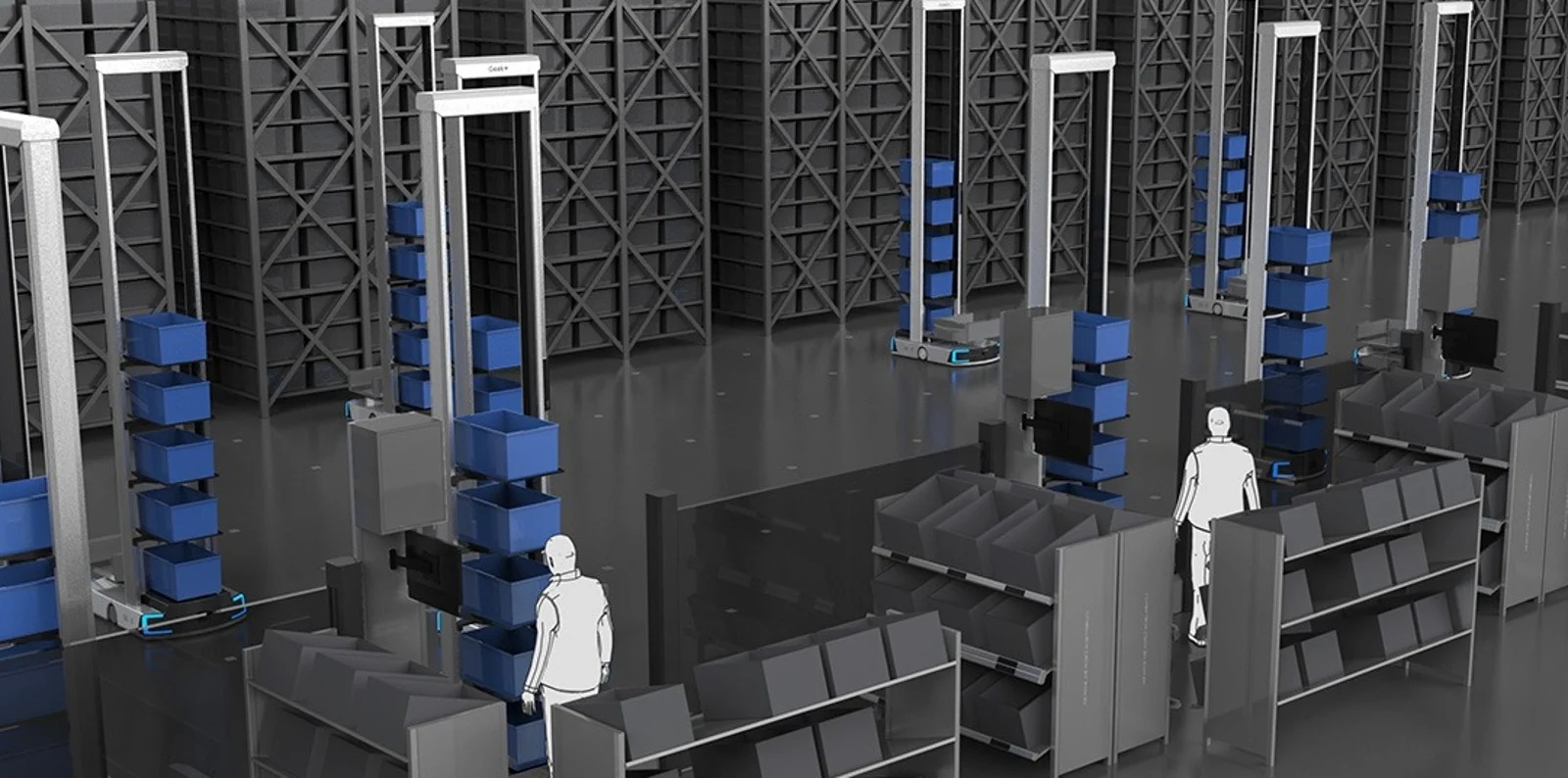

The game-changing picking system boosts efficiency improvement by 200%+

Goods-to-Person

Bin-to-Person

Dimension

L740*W560*H230

L950*W702*H275

L1090*W830*H275

L1310*W1020*H275

mm

Maxium payload

200

600

1000

1200

kg

Self weight

100

170

195

220

kg

Maxium lifting height

60

60

60

60

mm

Maxium lifting time

4

4

4

4

s

Maxium speed

2.5m/s without load,1.8m/s full load

2m/s without load 1.6m/s full load

2m/s without load 1.6m/s full load

1.8m/s without load,1m/s full load

m/s

Maximum rotation speed

90°/1.5s,180°/2s

90°/1.5s,180°/2s

90°/1.5s,180°/2s

90°/1.5s,180°/2s

°/s

Maximum slope angle

–

2.5° (slope 4.4%)

2.5° (slope 4.4%)

–

°

Stop accuracy

<10

<10

<10

<10

mm

Navigation

Inertial sensors + QR code

Inertial sensors + QR code

Inertial sensors + QR code

Inertial sensors + QR code

–

Obstacle detection distance

2m laser

2m infrared / 3m laser

2m infrared / 3m laser

3m laser

m

Power supply

Lithium-ion,DC50.4V,27Ah

Lithium-ion, DC50.4V, 39 Ah

Lithium-ion, DC50.4V, 39 Ah

Lithium-ion,DC50.4V,39Ah

–

Battery life

Full charging and discharging >2000 cycles

Full charging and discharging >2000 cycles

Full charging and discharging >2000 cycles

Full charging and discharging >2000 cycles

–

Run time

Charging 10 minutes working 2~3 hours

Charging 10 minutes working 2~3 hours

Charging 10 minutes working 2~3 hours

Charging 10 minutes working 2~3 hours

h

Certification

CE

CE、ETL、FCC

CE、ETL、FCC

CE

–

Payload size

700*700

880*880

1000*1000/ 1020*1220/ 1000*1200

1250*1250~1650*1650

mm

Working temperature

-20~50

-20~50

-20~50

-20~50

°C

Goods-to-Person Picking

Geek+ Goods-to-Person solution uses P series robots to move the inventory shelves and pallets to the picking station, completely eliminating the redundant walking of the picking workers, improving the accuracy of the picking, and reducing labor intensity. Compared to manual picking, the picking efficiency is improved by 2 to 3 times.

Maximum efficiency empowered by smart algorithms

Empowered by Geek+ proprietary smart algorithms, and the picking system uses the fewest robots to achieve maximum efficiency while improving the warehouse storage capabilities.

The main functions include:

- Combined order optimization and picking

- Dynamic wave selection process

- Inventory management and intelligent tally

- Adjustment of inventory layout

- Work station and robot task outline

- RFID technology integration

- Heat analysis and goods placement recommendation

- The shelf height is up to 2.8m and the storage capacity is increased by 20%.

Unmatchable advantages of picking system

Rapid ROI

- ROI in less than 3 years

- Lower initial investment required compared to traditional automation equipment

Increased Automation

- Reduces labor costs by 50% to 70% for goods-to-person picking

- Reduces labor intensity

High Efficiency

- +300% for goods-to-person picking

- 99.997% accuracy

- Easy to deal with the peak time

High Flexibility

- Flexible addition or removal of robots

- Customizable solutions for multiple industries

- No single point of failure

Rapid Deployment

- Full system deployment under 2 months

- Goods-to-person picking can deployed as fast as 2 weeks

- East to install on site, no ground fixed, flexible to transfer warehouse

Covering a wide range of application scenes

Geek+ Goods-to-Person Picking System is suitable for retail, third-party logistics, apparel, e-commerce, pharmaceutical, 3C, automobile manufacturing, and many other industries.

Single Bin-to-Person

- Small- to medium-sized parts picking; suitable for bin, tote, carton

- The robot can lifts the box to the most comfortable position for picking easily, to make the picking efficiency reach 3 times that of manual

Multi-layers Goods-to-Person

- Multi-tenants, high inventory capacity requirement, the order quantity fluctuates greatly and the order structure is complication

Combination Solution

- Movable re-bin wall

- Consolidated picking and order sorting

- Picktote cache & queue

- Robot arm

Bin-to-Person Picking

The Geek+ RoboShuttle™ bin-to-person picking solution can achieve high-density storage by using the innovative Geek+ C200 and narrow aisle design, while maintaining high efficiency.

Flexible bin handling, subverting conventional bin inventory model, ROI within 3 years

Dimension

L950*W702*H2500/3400

L1490*W870*H2500~5000

mm

Self weight

270

350

kg

Maximum payload

40

200

kg

Maximum lifting height

3400

5000

mm

Minimum lifting time

8

15

s

Maximum speed

2

1.8m/s

m/s

Maximum rotation speed

90°/1.5s,180°/2s

90°/1.5s,180°/2s

°/s

Maximum slope angle

2.5° (slope 4.4%)

–

°

Stop accuracy

<10

<10

mm

Navigation

Inertial sensors + QR code

Inertial sensors + QR code

–

Obstacle detection distance

2m infrared / 3m laser

3m laser

m

Power supply

Lithium-ion, DC50.4V, 39 Ah

Lithium-ion,DC50.4V,42Ah

–

Battery life

Full charging and discharging >2000 cycles

Full charging and discharging >2000 cycles

–

Run time

Charging 10 minutes working 2~3 hours

Charging 10 minutes working 2~3 hours

h

Certification

CE

CE

–

Payload size

400*300*250~600*400*350

400*300*200~600*400*500

mm

Working temperature

-20~50

-20~50

°C

Award-winning solution leading the industry innovation

The Geek+ RoboShuttle™ system was certified as “Best of Intralogistics 2020” by the world-renowned IFOY award, one of the industry’s most prestigious recognitions. Compared with the traditional shuttle system, RoboShuttle has higher flexibility, efficiency and return-on-investment.

- High box picking efficiency, up to 300 boxs / hour / station

- Flexible to fit customers’ existing shelves and lofts

- Fast implementation and low ground load

- Smaller investment and shorter payback period, ROI about 1~3 years

- Add or remove robots according to business waves easily

- No need for high-precision rails and easy to maintain

- Can be connected to a variety of automation equipment such as conveyor lines and other robots, which is convenient for integration and customized project deployment

Customers value

Rapid ROI

- ROI in less than 3 years

- Lower initial investment required compared to traditional automation equipment

High storage capacity

- Strongest single floor storage AMR solution, multiplies warehouse storage capacity by 2.5 times

- Make full use of height space which make the storage capacity is same as that of multi-shuttle

High Efficiency

- Ingenious ergonomic design makes the highest picking efficiency AMR solution ever, reach 3 times as manual’s

- 99.997% accuracy

High Flexibility

- Add or remove robots on demand, switch to manual picking easily

- Customizable solutions for multiple industries

- No single point of failure

Rapid Deployment

- Full system deployment under 2 months

- Reuse customers’ existing shelves and lofts, rapid deployment

Covering a wide range of application scenes

Geek+ Bin-to-Person Picking System is suitable for cosmetics, apparel, e-commerce, pharmaceutical, 3C, automobile manufacturing, and many other industries.

Single Bin-to-Person

- Small- to medium-sized parts picking; suitable for bin, tote, carton

- The robot can lifts the box to the most comfortable position for picking easily, to make the picking efficiency reach 3 times that of manual

Extended-Depth Bin-to-Person

- Small- to medium-sized parts picking; suitable for bin, tote, carton

- High density storage, up to 2.5 times as traditional shelf storage

Combination solution

- Goods-to-Person picking

- Robot arm

- Connection among multi-process