Industry-leading sorting system maximizes sorting efficiency

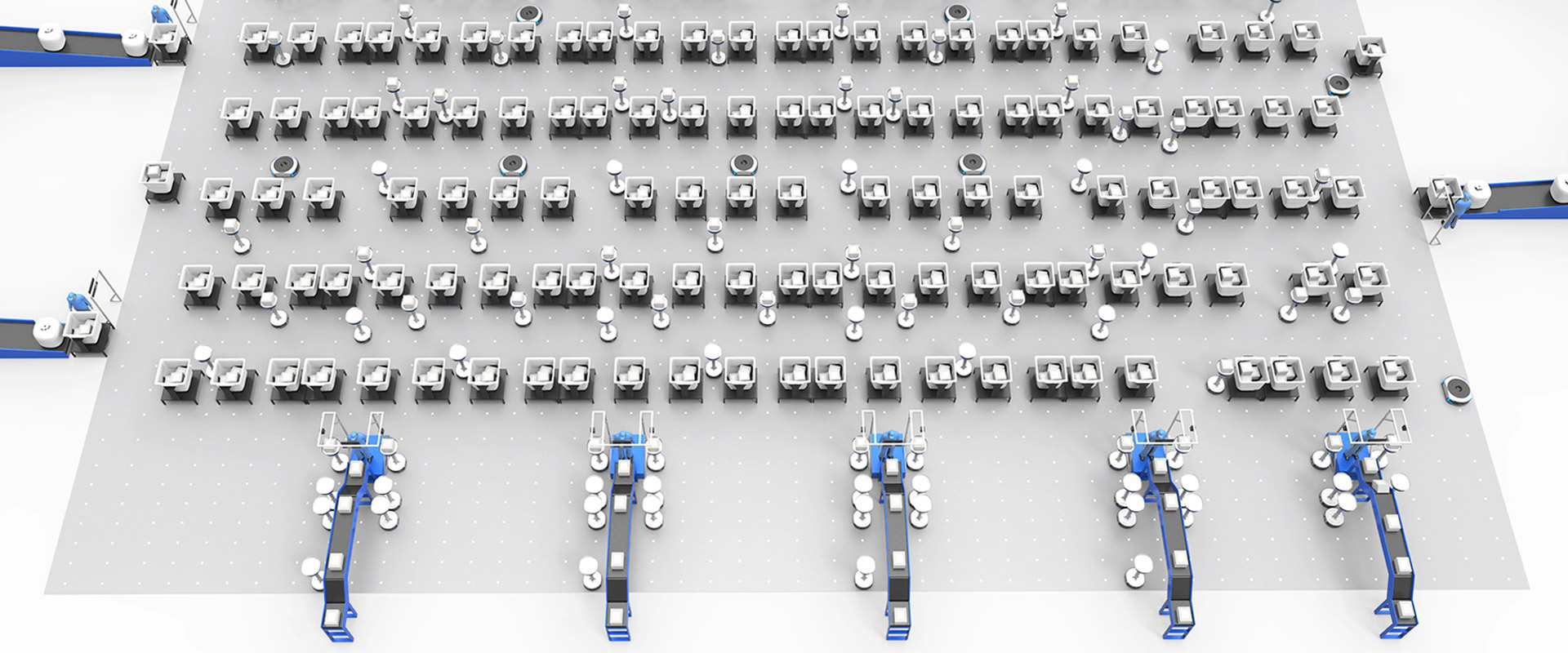

Floor-based Sorting

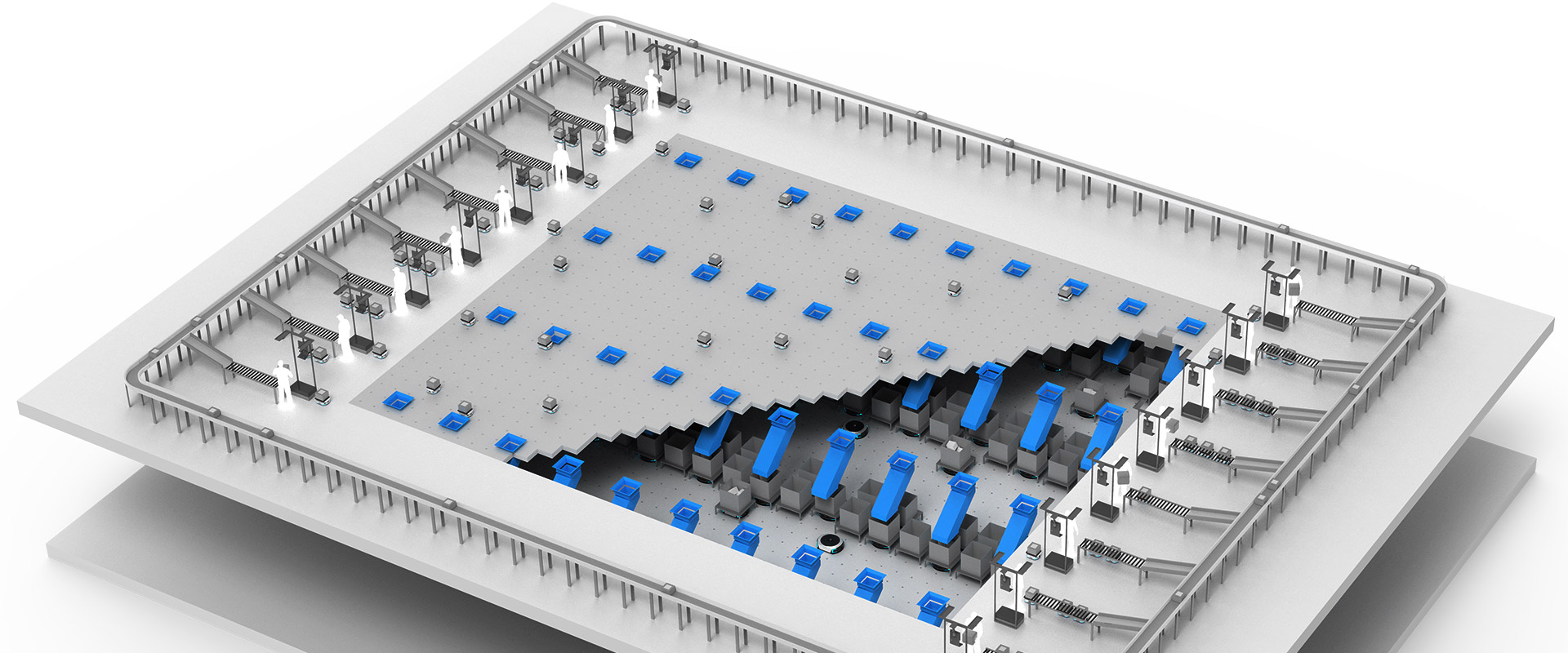

Multi-layer Sorting

Dimension

460 x 400 x 200

560 x 600 x 1027

560 x 510 x1335

740 x 560 x850

1170 x 832 x 540

mm

Self weight

18

75

70

150

210

kg

Payload

10

20

8

35

100

kg

Rotation diamete

560

750

560

/

1150 mm (Relative rotation of the belt)

mm

Maximum load size

400 x 400

600 x 420 x 400

500 x 400 x 300

640 x 460 x 300

1050 x 832

mm

Loading surface height

200

1000 mm, customizable

1250 mm, customizable

<850mm, Customizable

540

mm

Navigation method

Inertial + QR code visual navigation

Inertial + QR code visual navigation

Inertial + QR code visual navigation

/

Inertial + QR code visual navigation

–

Operation speed

2.5 m/s

2.5m/s (no load),2.0m/s (full load)

2.5m/s (no load),2.0m/s (full load)

2.5m/s (no load),2.0m/s (full load)

2.0

m/s

Positioning accuracy

< 10

< 10

< 10

< 10

< 10

mm

Battery

Lithium battery;DC24V,12Ah

Lithium battery;DC50.4V,12Ah

Lithium battery;DC50.4V,12Ah

Lithium, DC50.4V, 12Ah

Lithium battery;DC50.4V,39Ah

–

Operating time

Charging time: 10min Operating time: 2h

Charging time: 10min Operating time: 1.5h

Charging time: 10min Operating time: 1.5h

10 min charging for 1.5h full work

Charging time: 10min Operating time: 3h

h

Battery life

> 2000 cycles

> 2000 cycles

> 2000 cycles

> 2000 cycles

> 2000 cycles

–

Obstacle detection method

Infrared

LiDAR

LiDAR

LiDAR

Infrared/LiDAR

–

Obstacle avoidance distance

2.0

3.0

3.0

/

2m infrared light / 3m laser

m

Certification

/

CE

CE

CE

CE

–

Operating temperature

-20~50

-20~50

-20~50

-20~50

-20~50

°C

Communication

WIFI,IEEE802.11 a/b/g/n

WIFI,IEEE802.11 a/b/g/n

WIFI,IEEE802.11 a/b/g/n

WIFI,IEEE802.11 a/b/g/n

WIFI,IEEE802.11 a/b/g/n

–

Emergency stop

Available

Available

Available

Available

Available

–

IP rating

IP22

IP54

IP54

IP54

IP54

–

Floor-based Sorting

Geek+ Floor-based Sorting solution uses S20 series robots to sort small or middle-size parcels at the floor level. Empowered by strong algorithm, the solution monitors robot traffic and balances the task of each robot to achieve maximum sorting efficiency. It can be integrated with Geek+ moving robots to automatically transport packages and achieve unmanned automated sorting operations.

Multi-layer Sorting

With Multi-layer Sorting solution, the robots work on different level platforms, improving efficiency and utilization of warehouse space. Packing, sorting, and loading areas are highly integrated, optimizing the whole outbound process, realizing unmanned sorting operations.

Creating unmatchable values for clients

Rapid ROI

- ROI in less than 3 years

- Lower initial investment required compared to traditional automation equipment

- Scalable investment to fit business needs

More Automation

- Replaces manual sorting

- Increases sorting efficiency and accuracy

- Reduces labor intensity

High Efficiency

- 10x more efficient compared to manual labor

- Lowers labor costs

- Fully automated process management

High Flexibility

- # of robots can be adjusted with changing requirements

- Diverse range of robots to suit operational needs

Rapid Deployment

- Short deployment period

- Implementation in stages to fit business needs

Covering full application scenarios

Geek+ Sorting System is suitable for goods and parcel sorting, applicable to retail, apparel, pharmaceutical, 3C, FMCG, postal delivery, and other industries. Common sorting applications include:

Replenishment

Store replenishment and cross docking

Multi-combination with picking

Return

Expanded sorting capacity

Goods return and book return sorting

Fulfillment

Sorting after packing

Central distribution center parcel sorting